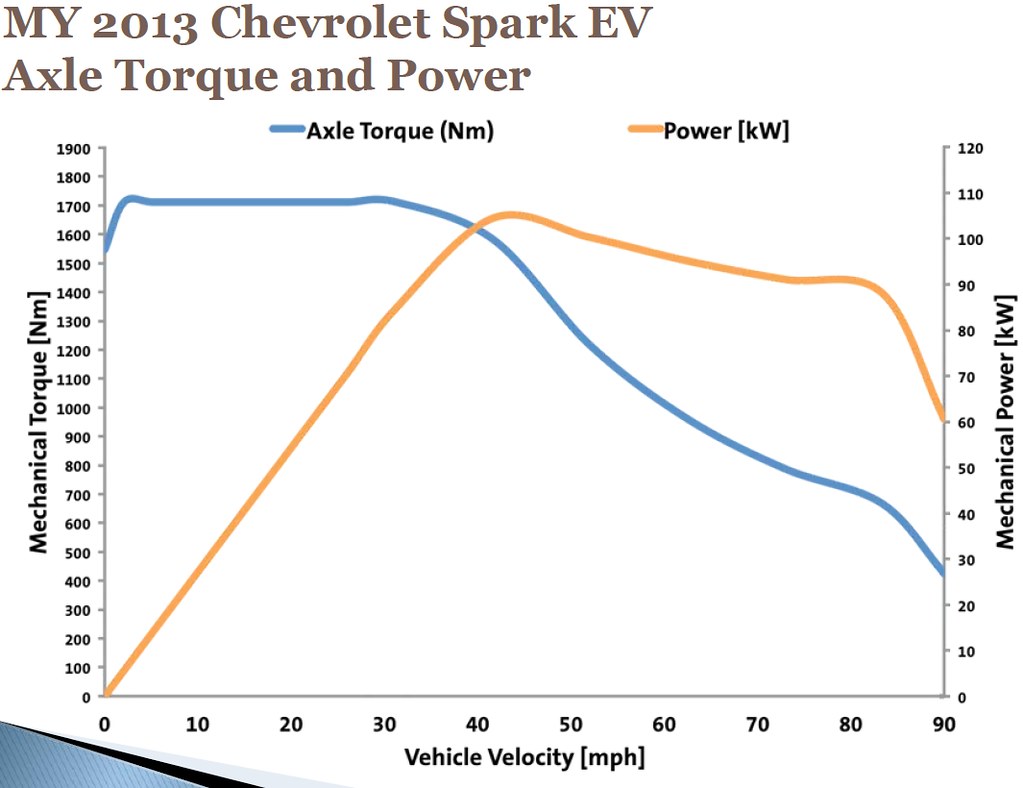

OK... I'm surprised that nobody has brought this up yet... But seems that this little tiger of a ride has a lot of potential for a software upgrade to tease out some more of that torque a little faster. I mean, 402 lb ft. of torque seems to be nicely spaced over the range of speed from the factory. Doesn't it seem possible to tune that for super-fast acceleration fun?

Now, I'm not advocating this - it is a Spark after all, and not at all designed for drag racing or high-speed anything for that matter. But wouldn't it be a fun idea to have a little "quick go!" boost mode every now and then?

The fact that souping-up a new technology and modifying electron control for dragster launches is Bad idea (this is a given), but that point aside, Does anyone on the forum have knowledge (or a good guess) on what might be possible to "tune" this little buggy for more quick take-off fun? Is it just software?

Now before any of you tree-huggers out there vote me off the forum - keep in mind, this is a very natural line of questioning; an expected evolution that is consistent with our great nation's love for automobiles. It happened with hot rods, tuner cars, and motorcycles ... It's a natural question to ponder. And, anyone who's driven a Tesla knows the potential fun I'm talking about here. And those motors don't generate 400 lb ft of torque either!! :shock:

Now, I'm not advocating this - it is a Spark after all, and not at all designed for drag racing or high-speed anything for that matter. But wouldn't it be a fun idea to have a little "quick go!" boost mode every now and then?

The fact that souping-up a new technology and modifying electron control for dragster launches is Bad idea (this is a given), but that point aside, Does anyone on the forum have knowledge (or a good guess) on what might be possible to "tune" this little buggy for more quick take-off fun? Is it just software?

Now before any of you tree-huggers out there vote me off the forum - keep in mind, this is a very natural line of questioning; an expected evolution that is consistent with our great nation's love for automobiles. It happened with hot rods, tuner cars, and motorcycles ... It's a natural question to ponder. And, anyone who's driven a Tesla knows the potential fun I'm talking about here. And those motors don't generate 400 lb ft of torque either!! :shock: